Esta web utiliza cookies para que podamos ofrecerte la mejor experiencia de usuario posible. La información de las cookies se almacena en tu navegador y realiza funciones tales como reconocerte cuando vuelves a nuestra web o ayudar a nuestro equipo a comprender qué secciones de la web encuentras más interesantes y útiles.

Why PIM&3D?

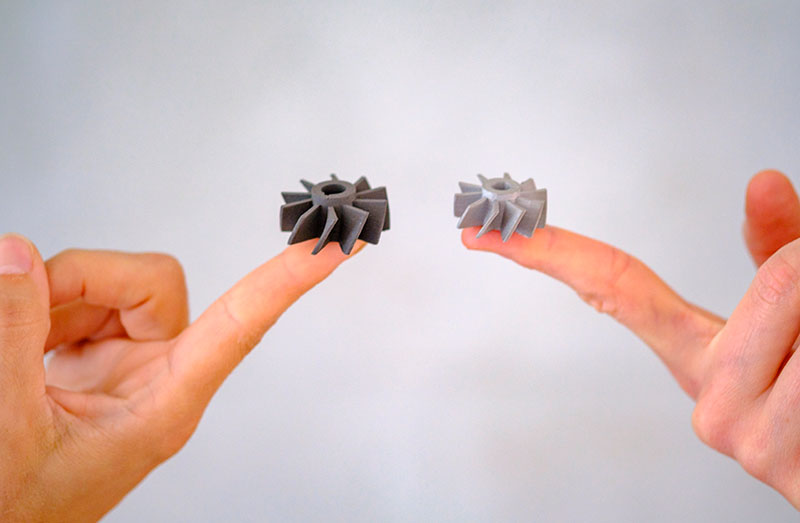

The promoters are well-recognized for an industrial R&D career focused on injectable mixtures formulation, binder design and materials processing technologies, leading the first pilot plant for PIM manufacturing in Spain. After developing different formulations for MIM and CIM in the latest 10 years, Blesol has started commercial production of high quality, ready-to-use feedstocks. The company is specialized in feedstock production and supply, not only providing widespread PIM materials for the most popular applications, but also on-demand products for specialized applications according to customer specifications. Moreover, production has expanded to include highly-filled filaments, which are capable of the production of 3D printed parts in conventional and cost-competitive printers and are also available within a broad range of metals and ceramics. The green printed parts can undergo similar post-treatments than green PIM parts to reach the final metal or ceramic component.

Our technology involves thorough cleaning protocols to discard any contamination between metals and ceramics

Blesol feedstock ensures the powder particles to have a high and uniform packing density, an isotropic and reproducible mould shrinkage and high dimensional stability during the whole process until the sintering completion. This homogeneity thanks to our compounding technology and the perfect granular form guarantees successful and continuous injection moulding, debinding and sintering processes. In addition, our technology involves thorough cleaning protocols to discard any contamination between metals and ceramics, as well as especial equipment and instruments for ceramic feedstocks, avoiding the incorporation of metallic particles due to abrasion effects, assuring the ongoing quality of the company